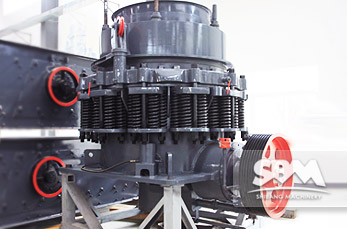

- 1.Crushing cavity shape is more. With the special design cavity, the user can choose to comply with production demand according to the actual situation;

- 2.It is widely used, and suitable for different size requirements of various materials crushing and products;

- 3.Low operation and maintenance cost, repair simple;

- 4.Safe and reliable, simple and easy to operate;

- 5.The balance of radial run-out operation ensures the most productive machine;

- 6.Spring safety system is fast and simple, clear cavity system can quickly be discharged from the host;

- 7.Dry oil seals anti-dust has the reliable sealing effect, effectively extending the lubricating oil change period and the service life of the parts.

| Model |

Movable Cone Diametermm (inch) |

Chamber Style |

Opening Side |

Closed Side |

Discharging Opening (mm) |

REV (r/min) |

Power (kw) |

Motor Model |

Capacity (t/h) |

Machine Size (mm) |

| Max.Feeding (mm) |

| CSB75 |

900 (3′) |

medium |

83 |

102 |

9-22 |

580 |

6-75 |

Y315S-6/75 |

45-91 |

2821×1880 ×2164 |

| coarse |

159 |

175 |

13-38 |

59-163 |

| CSD75 |

914 (3′) |

fine |

13 |

41 |

3-13 |

580 |

6-75 |

Y315S-6/75 |

27-90 |

2821×1880 ×2410 |

| medium |

33 |

60 |

3-16 |

27-100 |

| coarse |

51 |

76 |

6-19 |

65-140 |

| CSB160 |

1295 (4 1/4′) |

fine |

109 |

137 |

13-31 |

485 |

6-185 |

Y355M2-6/185 |

109-181 |

2800×2342 ×2668 |

| medium |

188 |

210 |

16-31 |

132-253 |

| coarse |

216 |

241 |

19-51 |

172-349 |

| CSD160 |

1295 (4 1/4′) |

fine |

29 |

64 |

3-16 |

485 |

6-160 |

Y355M1-6/160 |

36-163 |

2800×2342 ×2668 |

| medium |

54 |

89 |

6-16 |

82-163 |

| coarse |

70 |

105 |

10-25 |

109-227 |

| CSB240 |

1650 (5 1/2′) |

fine |

188 |

209 |

16-38 |

485 |

6-240 |

|

181-327 |

3911×2870 ×3771 |

| medium |

213 |

241 |

22-51 |

|

258-417 |

| coarse |

241 |

268 |

25-64 |

|

299-635 |

| CSD240 |

1650 (5 1/2′) |

fine |

35 |

70 |

5-13 |

485 |

6-240 |

|

90-209 |

3917×2870 ×3771 |

| medium |

54 |

89 |

6-19 |

|

136-281 |

| coarse |

98 |

133 |

10-25 |

|

190-336 |

| CSB400 |

2134 (7′) |

fine |

253 |

278 |

19-38 |

435 |

6-400 |

|

381-726 |

5200×4300 ×4700 |

| medium |

303 |

334 |

25-51 |

|

608-998 |

| coarse |

334 |

369 |

31-64 |

|

870-1400 |

| CSD400 |

2134 (7′) |

fine |

51 |

105 |

5-16 |

435 |

6-400 |

|

190-408 |

5200×4300 ×4700 |

| medium |

95 |

133 |

10-19 |

|

354-508 |

| coarse |

127 |

178 |

13-25 |

|

454-599 |

Jaw crusher is widely used in various materials processing of mining &construction industries, such as it is suit for crushing granite, marble, basalt, limestone, quartz, cobble, iron ore, copper ore, and some other mineral &rocks.

Supply the most current design and technical expertise;Supply parts sales and training service far beyond the initial sale;Your profits with quality parts and expert service.

Working Principle:

1) This crusher uses motor as its power. Through the motor's wheels, the eccentric shaft is driven by the belt and the belt wheel to make the jawstock move by a regulated track.

2)The angle between the toggie plate and jawstock will become large as the up of the jawstock. This will push the moveable jaw plate towards the fixed jaw plate,which can realize the multi-crushing of the materials.

3)The angle between the toggie plate and jawstock will become small as the down of the jawstock. The moveable jaw plate will leave the jaw plate at the presure of the tension rod and spring ,meanwhile ,the final products will be discharged from the dischargeing opening.