- The automatic control system can realize remote operation, and the operation is simple.

- The grinding roller and the grinding disc can't contact, and the grinding roller and the lining board are made of high quality material, to less abrasion and long service life.

- Maintenance is quick and convenient. The operation can realize in the outside of the machine body, reducing downtime.

- The quality of products is high, and in the same fineness grade condition, it can save 30%~50% of energy, and has good economic benefit.

- The system is working in confined pressure conditions. It can reduce dust to escape, reduce noise, clean environment, and full compliance with the relevant provisions of the state.

- The main machine adopts frequency control. It is more energy saving than electromagnetic adjustable speed, and high crushing efficiency.

- The design of roller sleeve and liner grinding curve is easier to form a material layer than the ordinary grinder, improving work efficiency.

- The grinding roller lubrication is using separate lubrication station. It can make the grinding roller bearing to obtain the full lubrication, and can avoid the oil storing too much and leakage phenomenon.

Model | LUM1125 | LUM1232 | LUM1436 |

Wheel diameter(mm) | 1100 | 1200 | 1400 |

Capacity (t/h) | 5~12 | 7~16 | 8~18 |

Fineness 400~650Mesh | ~D97 | ~D97 | ~D97 |

Material Size(mm) | <10 | < 10 | <10 |

Moisture | <3% | <3% | <3% |

Main Motor Power(KW) | 250 | 315 | 355 |

Roller(set) | 3 | 3 | 3 |

Classifier Motor Power | 15 KWx5 | 15 KWx7 | 15 KWx7 |

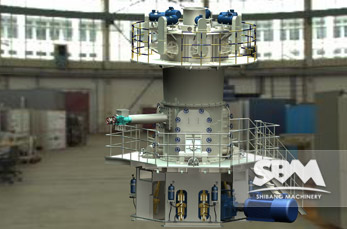

Now many large vertical roller mill machine manufacturers are some of the machine-building technology at home and abroad, based on years of experience and customer demand for the design and development of a new type of grinding equipment, such equipment the original grinding process The steps of the integration, first of all cement raw material or glass and other materials for coarse grinding and then drying the raw material for further processing, and finally then grinding and classification, it is this is an ideal device on, but because the machine production manufacturers of continuous research and development can become a reality.

Vertical roller mill can be applied to different production sectors, and even aluminum or coking time will use to it, it can be as large as the original bulk of material grinding, or the original powdered material further processing, so that the material is further processed to meet the requirements on the production.

Vertical roller mill has its own unique characteristics, one is said above to the grinding step, do not think of these steps seem very simple, shortly before these steps are operated separately, that operated separately increased the industry Production on the difficulty and requires a lot of manpower and material resources, but also led to a lot of waste of raw materials, is not conducive to the sustainable development of our country. While using the machine for the industry long ago environmental requirements are relatively high, most of them need to operate within the plant, but now the mill stand can be placed in the open air of the occasion, do not consider too many natural factors influence, can directly reduce the enterprises in the plant construction cost of inputs.

In order to minimize costs, energy consumption at work the mill stand is small and does not require excessive manpower to operate, as long as the button by far we can complete a series of operations. Manufacturers have also worried that once the mill stand will not cause a lot of wear and tear of its own, will not be in use for some time to be replaced after a machine, in fact, as long as you are operating properly in accordance with established procedures for using the mill regularly for professional opposition mill maintenance personnel to check, you do not worry about these issues, because the work is very stable vertical roller mill, to the greatest extent possible to avoid duplication of grinding, work process of reducing the loss of the machine, to avoid work Opposition during impact mill wall and destruction.

Supply the most current design and technical expertise;Supply parts sales and training service far beyond the initial sale;Your profits with quality parts and expert service.