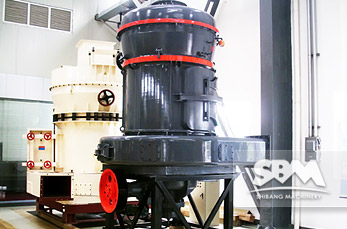

- Streamline appearance is beautiful and facilitates wind circulation, reduce resistance, reduce energy consumption;

- Isolation type cyclone powder collector, effectively improve the selecting powder rate and selecting powder accuracy;

- No resistance inlet vortex shell (small observation door without swirl), effectively avoid the eddy current effect, and reduce the energy consumption of the system;

- Duct support plate is arc-shaped, and conforms to the direction of the wind, making the wind unobstructed delivery of materials, reducing energy consumption;

- The shovel blade with replaceable surface blade, is high manganese steel, and makes convenient replacement and cost saving;

- The transmission system adopts a gear box and not reducer to transport, saving the installation position of reducer, and structure is more integration;

- The bevel gear is overall rotation, thus it has small energy consumption and high efficiency;

- Rare lubrication makes that the contact lubricating surface between bearing and thin oil is wider, to replace the first oil for three or four months, reducing customer costs.

| Name & Model | MTW110 | MTW138 | MTW175 | MTW215 |

| Ring Roller Number(pcs) | 4 | 4 | 5 | 5 |

| Major diameter of roller(mm) | Ф360×190 | Ф460×240 | Ф520×280 | Ф640x 320 |

| Inner diameter of roller (mm) | Ф1100×190 | Ф1380×240 | Φ1750×280 | Φ2150x 320 |

| Revolving Speed(rmin) | 120 | 96 | 75 | 65 |

| Max.Feed Size(mm) | <30 | <35 | <40 | <50 |

| Final size(mm) | 1.6-0.045,

fineness can reach to 0.038 | 1.6-0.045,

fineness can reach to 0.038 | 1.6-0.045,

fineness can reach to 0.038 | 1.6-0.075,

fineness can reach to 0.038 |

| Capacity(th) | 3.5-10 | 6.5-15 | 11-25 | 30-45 |

| Overall dimension(mm) | 8625×7933×8642 | 10920×9470×10227 | 12275×9555×9916 | 14730x 10860x 10341 |

| Main unit motor | Model | Y280M-6 | Y315M-6 | Y355M2-8 | Y3-355-4-8 |

| Power(kw) | 55 | 90 | 160 | 280 |

| Rotate Speed(rmin) | 980 | 990 | 740 | 740 |

Classifier speed regulating motor

(variable frequency motor) | Model | Y132M-4 | Y180M-4 | Y200L-4 | YVP280M-4 |

| Power(kw) | 7.5 | 18.5 | 30 | 90 |

| Rotate Speed(rmin) | 1440 | 1470 | 1470 | 1470 |

Centrifugal induced draft fan motor

| Model | Y250M-4 | Y315-4 | Y315L2-4 | Y315L2-4 |

| Power(kw) | 55 | 110 | 200 | 315 |

| Rotate Speed(rmin) | 1480 | 1480 | 1480 | 1480 |

Elevator

| Bucket Model | TH210 | TH315 | TH315 | TB315 |

| Motor Model | Y100L2-4 | Y112M-4 | Y112M-4 | Y160M-4 |

| Motor Power(kw) | 3 | 3 | 4 | 11 |

| Rotate Speed(rmin) | 1430 | 1430 | 1440 | 1440 |

| Jaw Crusher | Model | PE250×400 | PE250×750 | PE250×750 | PC1010 |

| Motor Model | Y180L-6 | Y200L2-6 | Y200L2-6 | Y315M2-6 |

| Power(kw) | 15 | 22 | 22 | 110 |

| Rotate Speed(rmin) | 970 | 970 | 970 | 990 |

| Magnetic Vibrating Feeder | Model | GZ2F | GZ3F | GZ4F | GZ5F |

| Power(kw) | 0.15 | 0.2 | 0.45 | 0.65 |

The MTW series milling machine is ideal machine for grinding barite, limestone, mica, talcum, quartz, calcite, granite, porcelain clay, basalt, gypsum, gold, iron ore, bauxite, copper, cement, coal etc. So it has wide application in powder making industry of construction, mining and paper-making and so on.

Supply the most current design and technical expertise;Supply parts sales and training service far beyond the initial sale;Your profits with quality parts and expert service.