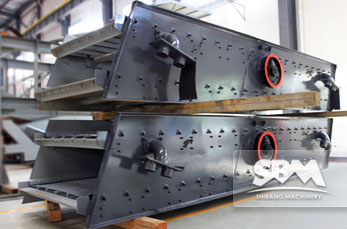

- The ring groove rivet connection has the advantages of advanced structure, firm and durable, flexible connection, stable operation.

- This series vibrating screen is circular vibrating screen; the material screen drip lines are long; the screening efficiency of multi-screening is high, and wide application.

- Have the advantages of simple structure and convenient repair.

- The structure is advanced; using eccentric block as an exciting force, has the advantages of excitation power, low power consumption, and low noise.

- The structure is small amplitude, high frequency, and large inclination, so this machine is high efficiency and large handling capacity.

- The vibrator adopts large clearance bearing and thin oil lubrication, so the noise is low, and the service life is long.

- The components have strong versatility, so the repair is convenient.

| Model | Screen Size (mm) | Layers | Mesh Size (mm) | Feeding Size (mm) | Capacity (t/h) | Power (kw) | Motor Model | REV (r/min) | Amplitude (mm) | Angle (℃) | Machine Size (mm) |

| 2YA1237 | 1200×3700 | 2 | 3-50 | ≤200 | 7.5-80 | 4-15 | Y160L-4/15 | 970 | 8 | 20 | 4010×2250×2660 |

| 3YA1237 | 1200×3700 | 3 | 3-50 | ≤200 | 7.5-80 | 4-15 | Y160L-4/15 | 970 | 8 | 20 | 4010×2250×3140 |

| 2YA1548 | 1500×4800 | 2 | 5-50 | ≤400 | 50-208 | 4-15 | Y160L-4/15 | 970 | 8 | 20 | 5120×2590×3060 |

| 3YA1548 | 1500×4800 | 3 | 5-50 | ≤400 | 50-250 | 4-15 | Y160L-4/15 | 970 | 8 | 20 | 5120×2590×3540 |

| 2YA1848 | 1800×4800 | 2 | 5-80 | ≤400 | 50-260 | 4-18.5 | Y180M-4/18.5 | 970 | 8 | 20 | 5120×2950×3060 |

| 3YA1848 | 1800×4800 | 3 | 5-80 | ≤400 | 50-300 | 4-18.5 | Y180M-4/18.5 | 970 | 8 | 20 | 5120×2950×3540 |

| 2YA1860 | 1800×6000 | 2 | 5-80 | ≤400 | 50-300 | 4-18.5 | Y180M-4/18.5 | 970 | 8 | 20 | 6260×2950×3480 |

| 3YA1860 | 1800×6000 | 3 | 5-80 | ≤400 | 50-350 | 4-22 | Y180L-4/22 | 970 | 8 | 20 | 6260×2990×3960 |

| 2YA2160 | 2100×6000 | 2 | 5-150 | ≤400 | 100-500 | 4-22 | Y180L-4/22 | 730 | 6-8 | 20 | 6270×3410×3670 |

| 3YA2160 | 2100×6000 | 3 | 5-100 | ≤400 | 100-500 | 4-30 | Y200L-4/30 | 730 | 6-8 | 20 | 6270×3470×4100 |

| 2YA2460 | 2400×6000 | 2 | 5-150 | ≤400 | 150-700 | 4-37 | Y225S-4/37 | 730 | 6-8 | 20 | 6270×3770×3610 |

| 3YA2460 | 2400×6000 | 3 | 5-150 | ≤400 | 150-700 | 4-37 | Y225S-4/37 | 730 | 6-8 | 20 | 6270×3790×4100 |

Vibrating Screen is widely used for grading and screening materials in the following fields: minerals, quarry, building materials, water conservancy and hydropower, transportation, chemical industry, smelting and so on. For material quality of screen mesh is changeable, the application is quite extensive.

Supply the most current design and technical expertise;Supply parts sales and training service far beyond the initial sale;Your profits with quality parts and expert service.

Working Principle:

1) This crusher uses motor as its power. Through the motor's wheels, the eccentric shaft is driven by the belt and the belt wheel to make the jawstock move by a regulated track.

2)The angle between the toggie plate and jawstock will become large as the up of the jawstock. This will push the moveable jaw plate towards the fixed jaw plate,which can realize the multi-crushing of the materials.

3)The angle between the toggie plate and jawstock will become small as the down of the jawstock. The moveable jaw plate will leave the jaw plate at the presure of the tension rod and spring ,meanwhile ,the final products will be discharged from the dischargeing opening.